A representative from our team will reach out to you soon.

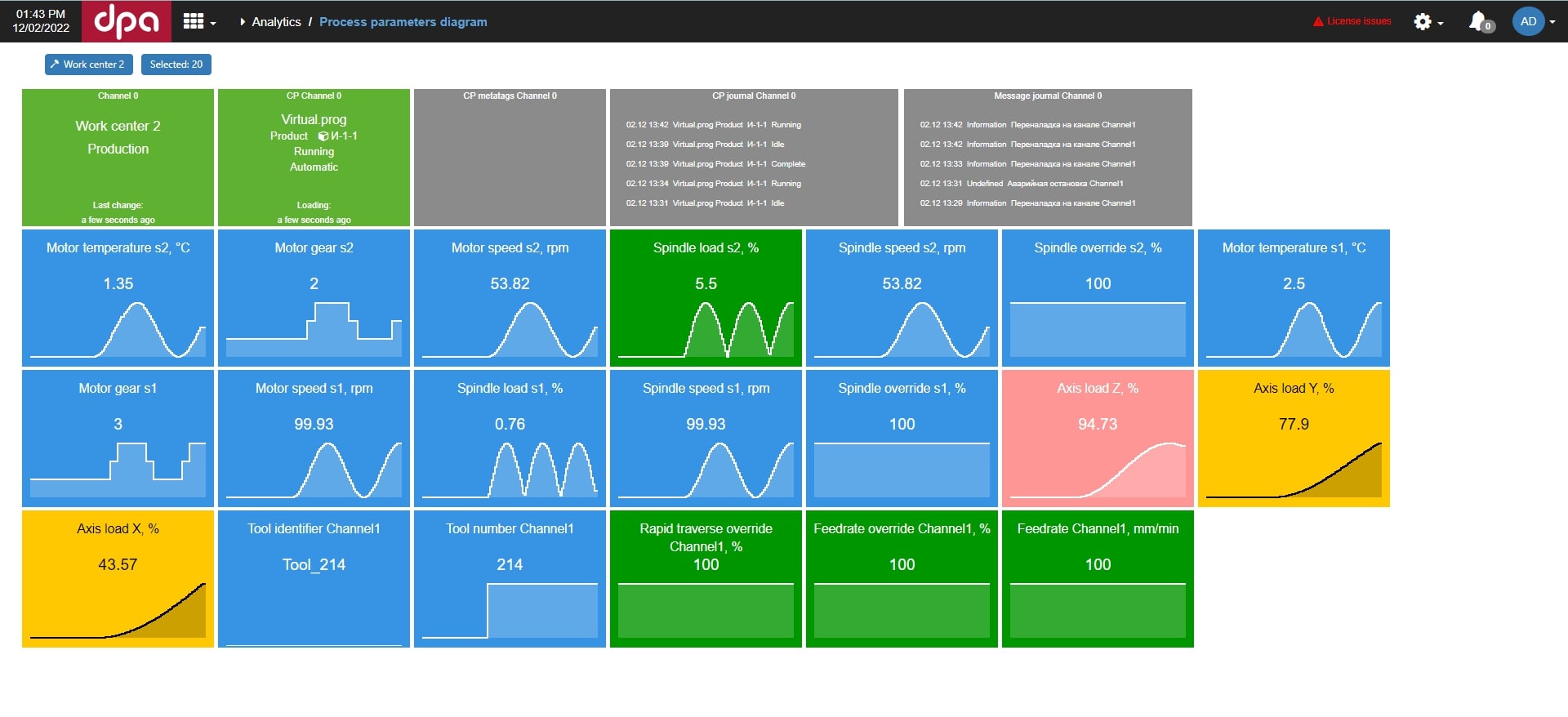

Real-time production monitoring and management system

for CNC machines

DPA offers a trustworthy information source for real-time management and handling of deviations

Scope of Applicability

-

Machining Process & Engineering Manufacture

-

Plastics Processing

-

Woodworking

-

Textile Manufacture

Benefits

Production System Maintenance

- Monitor Equipment State

- Prologning Machine Lifetime

- Stabilize work on technology

- Control Operation Duration

- See Emerging Problems and Solutions

Basis of order execution on time

- Control Production

- Predict Turnaround Time

- Sustain Turnaround Time

- Execute in Reasonable Time

- Orders on Time

Product and Production Processes Improvement

- Technology Debug

- Technology Upload

- Technology Control

- Technology Comparison

- Technology Observance

Functional modules of the system

Data Integration

ERP Actualization

Business processes supported by automated control systems will be more efficient by supplying reliable production information automatically. Monitoring systems transmit information on quantitative and temporal indicators directly to the ERP system.

MES Basis

Monitoring can be the basis for the MES development (Full-function Production Management System). Already today's functionality allows taking control of basic processes and getting a clear benefit. It is therefore possible to consider the further development of the production system accordingly.

PLM Development

There is a rationale to focus on the integration of PLM-MDC (moving from “Digital Part” to “Digital Production”) for enterprises with complex products and a well-developed circuit (CAM / CAD / CAE / PLM).

COMPATABILITY WITH NC machine TYPES

Advantages

Uniform environment for all productive groups

DPA is one of the most functional systems and all the necessary components for control CNC machines can be installed on the same equipment.

No additional equipment

Ethernet network connection is all that's needed to establish a connection with the machine. Our system seamlessly integrates with a wide range of CNC machine types, ensuring compatibility with all the popular models in the market.

Remote access from any device

Our DPA interface adheres to the HTML5 standard, offering universal accessibility. No matter your location, all that's required to access the system is a web browser and an Internet connection.

Rapid Implementation

Our modular system, combined with our preconfigured drivers, is suitable for a wide range of tools, enabling swift integration for your specific needs.

Low Cost

The quick-connect feature for tools and the absence of any additional equipment requirements significantly reduce implementation costs.

Flexibility and Universality

We offer versatile integration options for virtually any tool, even those lacking external connection interfaces.

Free Trial

Complete the application, and our experts will assist in setting up the equipment for a free trial at your enterprise