A representative from our team will reach out to you soon.

DPA or SCADA?

DPA or SCADA?

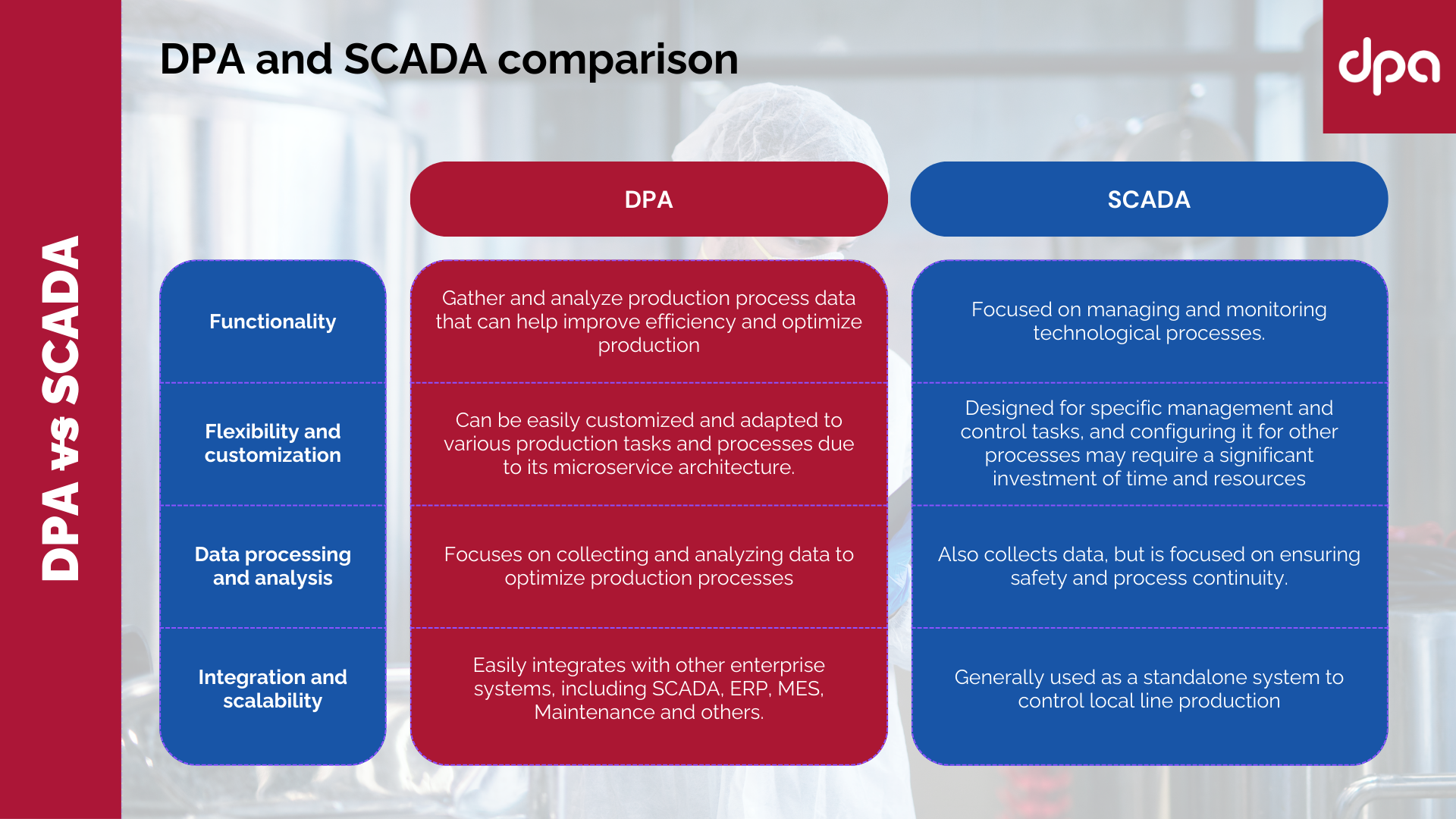

Is DPA similar to SCADA? This question often arises among potential clients or partners unfamiliar with industrial equipment monitoring systems. While they may seem similar at first glance, important differences lie in the details.

SCADA systems are specifically designed for controlling and managing technological processes. In contrast, DPA, with its flexible microservice architecture, adapts to a wide range of production tasks. This flexibility enhances overall efficiency and optimizes various aspects of production, such as reducing human error, identifying causes of defects, minimizing equipment downtime, and calculating Overall Equipment Effectiveness (OEE).

Both systems gather data, but for different purposes. SCADA ensures process safety and continuity, whereas DPA emphasizes data collection and analysis. This data is useful not just on the production floor but also for a broader audience, from machine operators to board members and shareholders. DPA comes equipped with features like dashboard visualizations and analytics, saving time compared to implementing similar features in SCADA.

DPA can be seen as complementing SCADA by using it as an additional data source. Moreover, DPA seamlessly integrates with other enterprise systems like ERP, MES, and MRO. This integration enhances data-driven management capabilities across the manufacturing enterprise, a task that is often complex and time-consuming with SCADA.

#DPA #MDC #SCADA #Manufacturing #Technology #MonitoringSystems

DPA is

A multi-layered system designed for gathering, visualizing, and managing data on production equipment operations. It facilitates real-time production process management using the OEE (Overall Equipment Effectiveness) system. The system aggregates and processes data from CNC machines, capturing information on effective utilization and idle downtime

Breaking News

Launching Our Revolutionary OPC UA Server for PICANOL Weaving Machines

We are proud to unveil our innovative OPC UA server designed specifically for PICANOL weaving machines equipped with "Plus" and "BlueBox" control systems.

06/03/2024Major Breakthrough for DPA: First Contract in Armenia!

We are thrilled to announce our first contract with Grand Tobacco - the leading cigarette manufacturer in Armenia.